07, 2019

by oreelaser

Since the mid-1950s, the plasma arc cutting technology embark upon a industrial venture, it mainly use mixed argon and hydrogen gas as the working gas (the working gas cost is high). In comparison, laser cutting technology was popularized later. With the penetration of international laser cutting technology and the expansion of the international market, the birth of the first laser cutting machine in the 1960s expanded the cutting technology field of metal and non-metallic materials, making the cutting of high-precision workpiece have a more rapid and vigorous development momentum. As of 2017, the market share of laser cutting machines is about 45%, and the laser cutting machine market is still showing rapid growth and strong demand.

Principle - the two working principles are also different: plasma cutting mode is mainly based on high-temperature plasma arc, supplemented by ion gas to discharge molten material, while laser cutting mode is based on high-strength laser beam, supplemented by high-pressure gas to blow out molten slag.

Environmental protection - in terms of energy, laser cutting mode is mainly based on optical energy. Compared with plasma-cut arcs, its energy is cleaner and there is no dust and no arc overflow. It is closer to national environmental protection policies;

Cutting thickness - plasma cutting mode is mainly for cutting medium-thickness plates (taking 260 amp plasma cutting mode as an example, the maximum cutting thickness can reach 6cm), while laser cutting mode is mainly for medium-thin plate cutting (taking a 4000 watt laser cutting mode as an example, the maximum cutting thickness is 2.5 cm).

Speed - in the cutting of medium and thin plates (take 8mm plate as an example), the laser cutting rate is higher than plasma cutting and dominates at 10m/min; while for thick plates (for example, about 20mm plate), plasma cutting The rate is higher than the laser cut, but the relationship between the plasma cut roughness and the sheet thickness is close to a proportional relationship.

Accuracy - the laser cutting positioning accuracy is 0.05mm, and the repeat positioning accuracy is 0.02mm, which is far from being achieved by plasma cutting. For the precise cutting demand that is currently developing rapidly, both the handicraft industry and the heavy-duty processing industry will develop to a high degree of refinement, and consumers' requirements for precision of finished products can only be higher and higher.

Cutting materials - Laser cutting has a wide range of options (metal, non-metal, ceramic, glass, etc.) and covers a range of materials for plasma cutting.

Range of application - The material cut by the plasma cutting machine has a cutting surface with a slope of 0.5-1.5 , and the slit is easily hardened. But for laser cutting mode, the cutting speed is faster, the processing precision is higher, the slit is very narrow, and generally no subsequent processing is required.

For example, large-scale processing enterprises that require extremely high precision for accessories such as aero-engine manufacturers mainly use laser-cut, and there is almost no demand for plasma cutting.

Taking construction engineering and contracting services as examples, to some extent, the requirements for workpieces are more stringent. Laser cutting is the main cutting method to prevent the structure of the crucible from being tightly attached.

Taking the container freight box manufacturing enterprise as an example, this type of enterprise is not very strict with the precision of the processing of scattered workpieces, mainly using plasma cutting as the main cutting method, supplemented by laser cutting method;

For auto parts and accessories manufacturers, different workpiece requirements are different, mainly adopting mixed cutting method, including: laser cutting, plasma cutting, CNC flame cutting, shearing machine, etc.

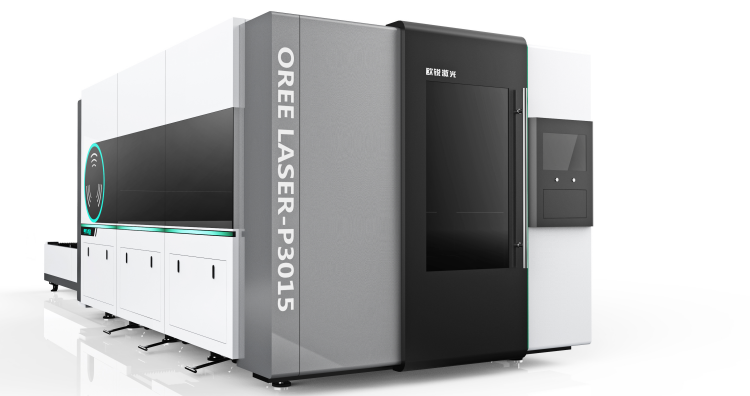

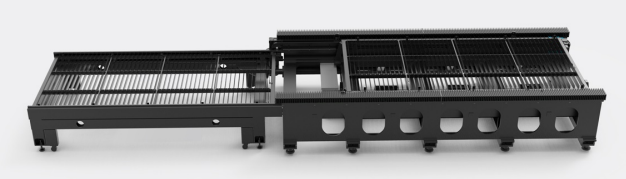

Professional Laser Cutting Machine Manufacturer - OreeLaser